The world is rapidly changing, If you are interested in learning how to design 3D objects and do not know where to start, this course is for you. It is designed for beginners and breaks down each step of creating a 3D model using Tinkercad. The software allows you to create 3D models that can then be sent to a 3D printer to be made. If you are interested in learning how to create your own models to print on your 3D printer then Tinkercad is the best place to start. It is fairly simple to use, allows you to create a wide range of objects, and best of all, the software is completely FREE! This course includes:

- Content with 50+ hours

- 20+ Assignments

- 15+ Quizzes

- Full lifetime access

- Course Completion Certificate

What You’ll learn?

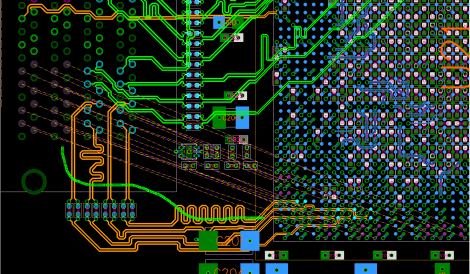

- What is 3D designing.

- Tinkercad and its features.

- How to create custom 3D models for use with games, movies or 3D printing.

Who is this course for?

- Anyone that wants to learn 3D design

- Anyone that wants to learn Tinkercad

- 3D Printing

- Designers

Requirements:

- No prior experience.

- Only laptop\ desktop required. [any platform (Windows, Linux Etc.) will work]

- A physical mouse is recommended.

Description- Tinkercad is a free, online 3D modelling program that runs in a web browser, known for its simplicity and ease of use. It has become a popular platform for creating models for 3D printing as well as an entry-level introduction to constructive solid geometry in schools. TinkerCAD is also great for kids to learn as its simple and colourful interface make it fun to learn and create. After taking this course you will be able to teach your children to model a wide variety of objects limited only by their imagination. The course also includes some quizzes to help you ensure you understand the basics of TinkerCAD before moving on. 3D printing is fast becoming one of the easiest ways to create your own objects at home. It’s becoming more and more popular every day and the ability to create objects yourself rather than relying on finding objects created by others will become a more important skill in the future. You’re going to love learning 3D designing. It’s one of those skills that once learned will open up all kinds of opportunities like when it comes to special assignments and projects. Hobbyists will discover the power of 3D design and how it can help take their hobbies to a new level.